In the ever-evolving landscape of industrial packaging, horizontal form fill seal machine efficiency and precision are paramount. Among the arsenal of tools aiding this endeavor stands the humble yet indispensable seal machine. This innovative apparatus not only streamlines packaging processes but also ensures product integrity and security. In this article, we delve into the workings, benefits, and future prospects of seal machines in modern packaging operations.

Understanding Seal Machines:

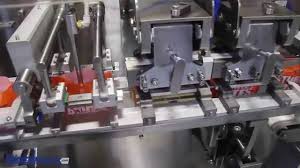

Seal machines, also known as sealing machines, are mechanical devices designed to seal various types of packaging materials. From pouches and bags to containers and cartons, seal machines cater to a diverse array of packaging needs across industries such as food and beverage, pharmaceuticals, electronics, and beyond.

Key Components and Mechanisms:

At the heart of a seal machine lies a combination of heating elements and pressure mechanisms. These elements work in tandem to create airtight seals on packaging materials, ensuring the contents remain fresh and intact throughout storage and transit. Additionally, advanced seal machines often incorporate features such as temperature control, adjustable pressure settings, and sensor-based monitoring systems for optimal performance.

Types of Seal Machines:

Seal machines come in different configurations to accommodate various packaging requirements. Some common types include:

- Heat Sealers: Utilizing heat to melt packaging materials together, heat sealers are ideal for sealing plastic films, laminates, and pouches.

- Vacuum Sealers: Employing a combination of heat and vacuum pressure, vacuum sealers remove air from packages before sealing, prolonging the shelf life of perishable goods.

- Induction Sealers: These machines use electromagnetic induction to seal caps onto containers, ensuring tamper-evident closures for products like pharmaceuticals and beverages.

Benefits of Seal Machines:

The integration of seal machines into packaging workflows offers several noteworthy advantages:

- Enhanced Product Protection: By creating hermetic seals, seal machines safeguard products against moisture, contaminants, and tampering, preserving their quality and integrity.

- Improved Efficiency: Automation features in modern seal machines streamline packaging processes, reducing manual labor and increasing throughput rates.

- Cost Savings: Through precise sealing and reduced material waste, seal machines contribute to cost efficiency in packaging operations.

- Compliance and Safety: Seal machines help companies comply with regulatory standards regarding packaging integrity and product safety, fostering consumer trust and confidence.

Future Trends and Innovations:

As technology continues to advance, the landscape of seal machines is poised for further innovation. Anticipated trends include the integration of artificial intelligence and machine learning algorithms for predictive maintenance, enhanced seal inspection systems for quality assurance, and the development of eco-friendly sealing materials to support sustainability initiatives.

Conclusion:

In the realm of industrial packaging, seal machines serve as indispensable tools for ensuring product protection, efficiency, and compliance. As manufacturers strive for greater automation and sustainability, the evolution of seal machine technology promises to play a pivotal role in shaping the future of packaging operations. With their ability to deliver reliable seals and operational efficiency, seal machines are set to remain a cornerstone of modern packaging solutions.